Certain manual tasks steal a huge amount of time from operators. They pull people away from more important work and reduce the quality of people’s jobs.

这样的工作是飞机洗涤。航空航天制造中的这项重要任务不会为该过程增加直接价值,但它很重要,因为它可以通过减少腐蚀来延长平面的寿命。

The task needs to be done but it would be much better if human workers did not have to do it!

韦尔德系统那an automation supplier based in Austin, Texas, USA, has developed a highly effective system for automating the task of airplane manufacturing. They did this by using RoboDK for programming. Their system provides aerospace with a way to reduce the time to perform this task by a whopping 95%!

手动洗涤飞机的问题

Washing is a critical task in airplane manufacturing as it helps to reduce corrosion, improving the life of the plane and its safety.

The conventional method of airplane washing involves the use of sponges, brooms, rags, and ladders. A team of 4 mechanics would usually take 4 hours to wash a plane manually, taking a total of 16 person-hours.

The entire task often takes up the whole day, making both the people and the plane unavailable for that time. During that time, they are unable to perform higher-value work.

Plane washing is also a dangerous and labor-intensive process. Working at height while standing on wet, slippery surfaces can lead to injury.

介绍Wilder Systems.

韦尔德系统专业从事飞机制造商的经济高效的机器人解决方案。

他们描述了他们的使命“通过将机器人引入航空航天制造和维护来扩展可行机器人应用范围。”

该团队使用各种机器人技术来做到这一点,包括移动机器人,龙门机器人和协同机器人。

进入“驱动器 - 通过”机器人洗涤系统

The team at Wilder Systems realized that the conventional approach to aircraft washing was inefficient. They knew that they could use robots to wash airplanes more efficiently and with less risk to humans.

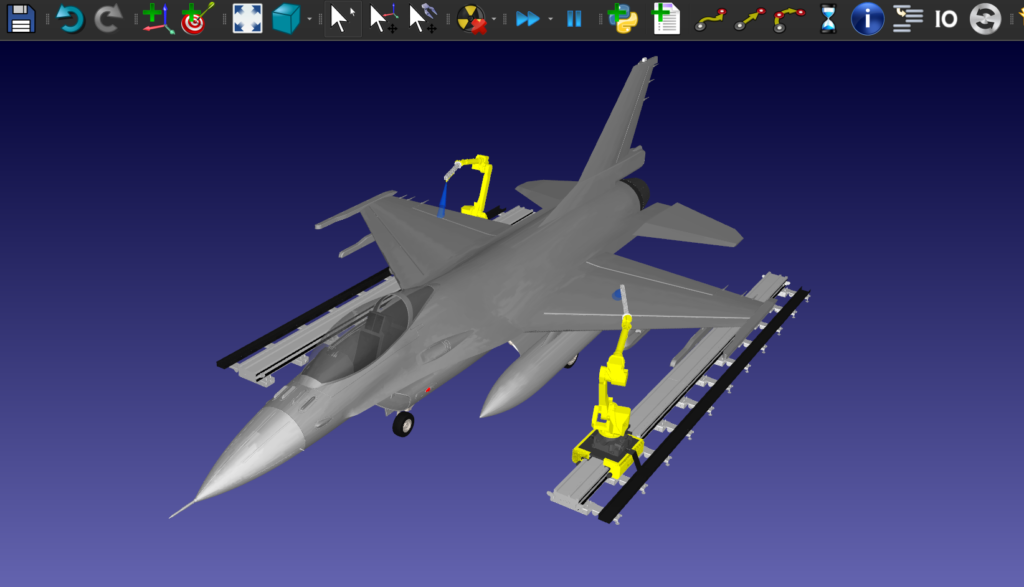

该项目的目标是减少劳动量,并提高洗涤F-16飞机的安全性。为此,他们设计了用于飞机的第一个机器人“驱动器”洗涤系统,利用多种机器人组件。

该系统提供更安全,更快的洗涤解决方案,消除了停机时间。

与手动洗涤过程的16人小时相比,该系统利用机器人而不是人,整个洗涤循环在仅52分钟内完成。如果一个人需要监督机器人,这将是节省95%的时间。然而,由于机器人可以单独操作,因此节省的距离较近100%的人在人间节省。

团队的机器人设置

机器人系统使用诸如Wilder Systems的团队的各种现成硬件和软件组件的组合集成到自包含的洗涤单元中:

机器人硬件

The hardware of the application is based around core components of:

- 扇形6-axis industrial robots —机器人操纵器执行任务的洗涤功能,沿着编程路径将清洁头移动在飞机上。

- PLC communication —与许多机器人应用一样,可编程逻辑控制器提供系统的不同硬件组件之间的协调。

- Hydraulic pump systems and auxiliary equipment —申请的“业务结束”是洗涤系统。这使用液压泵系统通过机器人的清洁末端效应器将水推进到脏飞机上。机器人通过IO进行通信,在发泡和冲洗喷雾器之间切换。

The Software Setup

The basic software components of the system are:

- Robodk -机器人编程是由罗布克,这使得离线编程方便快捷ayx官方or both new and experienced robot programmers. The 3D model was imported from Autodesk Fusion 360, which integrates directly with RoboDK through a插入。

- PLC编程- 团队选择使用PLC编程来组合硬件组件。Various RoboDK users已成功纳入PLC和离线编程。ayx官方

该项目的主要程序员Alejandro Rengel解释了Robodk允许他在这个项目中实现:

“RoboDK was the essential tool that allowed us to develop the world’s first-ever robotic plane wash. Using CAD-To-Path strategies, we were able to generate robot paths that were adaptive and error-proof.

罗布克helped me transform from an entry-level programmer into an advanced programmer through their easy-to-use GUI, abundance of training resources, and phenomenal customer service.”

使用了哪些Robodk功能

Rengel和团队使用了多个Robodk的功能来创建这个独特的应用程序。两个机器人被编程为遵循CAD数据生成的路径,同时保持彼此之间的同步。

Robodk的铅产品经理JérémyBrouillard解释说:

“在这个复杂的项目中使用了许多Robodk功能。Wilder Systems使用“教导曲面上的”功能来编程飞机的前半部分。它们定义了正确的洗涤角,并单独点击板表面以定义机器人轨迹。要完成它,他们可以通过使用Robodk的Python API镜像飞机的下半部分的程序来保存一半的工作。“

他们使用的Robodk功能包括:

- 同时模拟两个机器人。

- 外轴扩展机器人的范围。

- 只需点击平面的表面,“教导表面”以定义轨迹。

- 罗布克’s Python API to generate a mirror of the paths for the opposite side of the plane.

- 扇形后处理器to generate code to run on the robot controller.

下一步是什么?

For Wilder Systems, washing is just the start.

团队计划为其他复杂和耗时的飞机维护任务使用同样的机器人平台。这包括适应和重新粉刷,面板钻探和非破坏性检查。他们将使用机器人洗涤申请作为这些未来增强的培训机会。

他们还计划通过将其安装到移动和自主平台上进一步提高系统的敏捷性。这允许它们在整个飞行线上执行操作。

目前从操作员窃取时间的手动任务?在下面的评论中告诉我们或加入讨论linkedin那Twitter那Facebook那Instagram那or inthe RoboDK Forum.